Her mast is down on the rails for transport. I would have liked to have better support for the mast, but I didn't have time. Since I don't have a truck to haul it, I had to take advantage of transportation when it was offered. Fortunately, I only had to haul her 15 miles, and the roads were good.

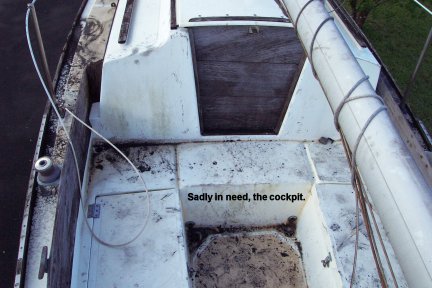

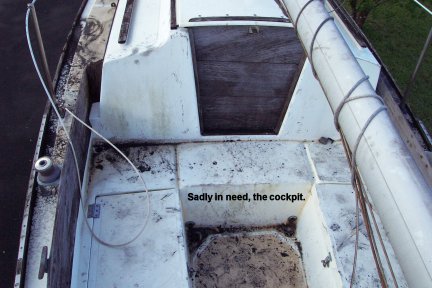

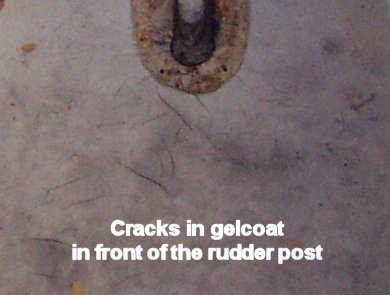

The condition of her deck was appalling. There was an accumulation of grime and rotting debris. The years had been especially hard on all of the exterior teak and horizontal gelcoat surfaces due to the brutal Florida sunshine. There is some crazing and worrisome cracking of the gelcoat, particularly in the cockpit. All of the exterior teak had weathered black and was deeply grained.

Here you see the bow. The forward hatch, intended to be translucent by elimination of the gelcoat, shows the environmental degradation of the polyester resin and exposure of the glass fibers. which appear as white patches. The blue tarp covers the mast step, to avoid rainwater intrusion into the steel support beam of the cabin top.

As you can see, I had already begun stripping the boat by removing the rub rail and the toe rail to inspect the hull-deck joint.

Here is a view of the stern. I had already removed the lazaret hatch. One ventilator cowl on the lazaret cover was missing. The hinges on the cockpit hatches were broken and had been removed by the time of this photograph.

Some of the worst gelcoat cracks were in the cockpit floor, but the floor was solid with no indication of sponginess or flexing, so I was pretty sure the cracking did not extend into the underlying fiberglass. I suspect it is a result of daily environmental heating and cooling cycles of the Florida sunshine.

In fact, I found no soft areas anywhere on deck. The only indication of any core damage from water intrusion was on the lazaret hatch, radiating around the holes cut for the ventilator cowls. They had not been sealed.

I wish this was a better photo, because the coamings and Companionway drop boards are in worse shape than it seems here. The grain was so eroded than in some areas the relief was 1/4 inch deep. In addition, the drop boards were warped, and therefore difficult to install or remove.

I planed the drop boards to remove the warping and the raised grain. They are now a little over 1/4 inch thick; much too thin to be used for this function.